|

Metal 4 U | Metal Spinning, Plasma Cutting

Talk to one of our friendly staff today. Call: 02 4872 3939 Email: [email protected] |

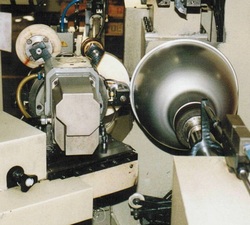

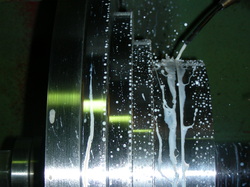

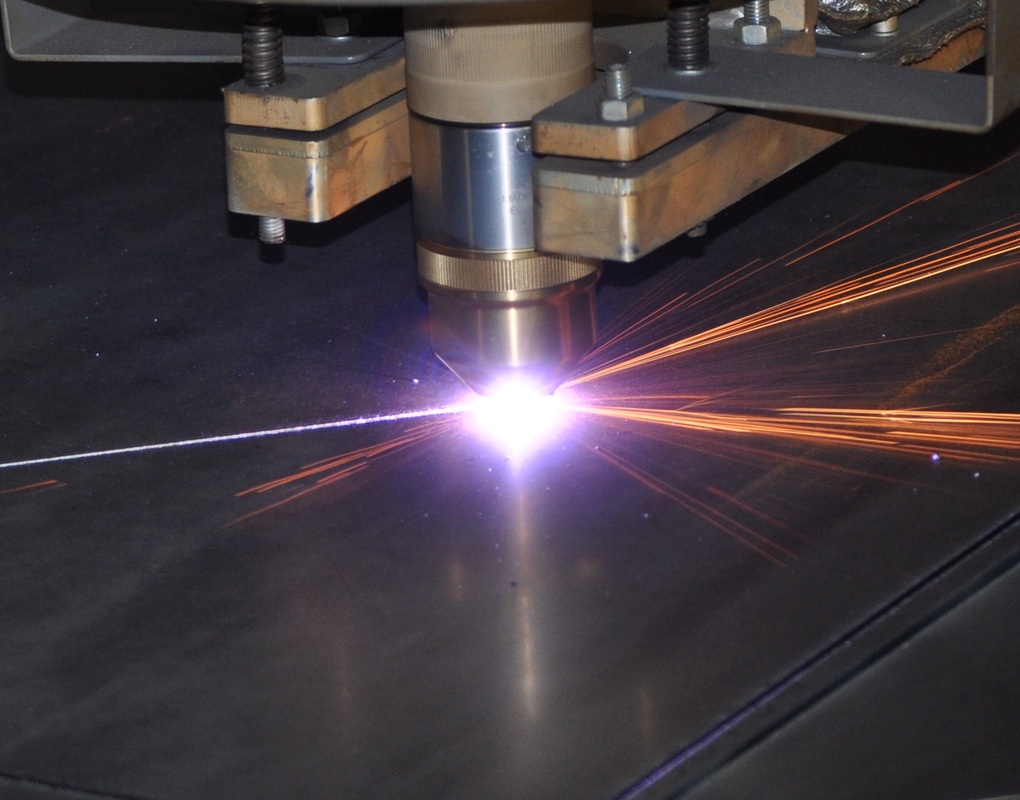

In Need of Top Notch Metal Cutting near Nowra? You’ll Find Incredible Sheet Metal Fabrication Services through Metal 4 UWorking with metal is a fine art that not everybody can handle. However, metal is used in many major building and innovation projects, from automobile creation right down to small parts and machinery. Of course, to ensure your metal fits perfectly, you’ll need an effective way to cut it down to size. Cutting, reshaping, and even bending metal is an industry all by itself, and takes a highly qualified team with the right tools and machines. Sheet metal fabrication is the process of bending, altering, or even shrinking sheet metal to match a particular specification. While many companies work daily with metal, most of them do not have the right resources or knowledge to properly fabricate sheet metal. If your business is in need of the best sheet metal fabrication services near Nowra, reach out to the top name in the game: Metal 4 U. Learn More about Metal 4 U and Their Sheet Metal Fabrication near NowraMetal 4 U is located in Mittagong, not far from Nowra. Our company is firmly dedicated to producing the highest quality metal products and services in the area and won’t rest until you’re satisfied with your project. We provide many metal services, from metal spinning to laser cutting to toolwork. We’re the professional team you want on your side for any metal fabrication job. We’re well known for our laser cut metal screen projects, as well as our metal fabrication offerings. We also offer superior customer service and will make sure you understand every aspect of your metal project, so there are no surprises. Our company also competitively prices all of our metal services and projects, so you know you’re always getting the best deal out there. How Does Metal Fabrication Work? In short, metal fabrication is performed to alter the size or shape of the current metal. This can be used when building different parts or products. There are many different ways to fabricate sheet metal. Metal shaping includes bending, shrinking, cutting, or stretching metal. While some of these methods do not require special tools or machines, they do require a skilled eye. Metal breaking is another aspect of sheet metal fabrication, which can bend your metal up to 90 degrees. Cutting involves shears, grinders, or plasma cutters, and should always be handled by a professional. Shrinking metal is also possible and can be done by tucking, using a shrinker tool, or through heat. There are also different ways to stretch out metal, including using a stretcher or wheel. Metal fusion or welding makes up one of the last aspects of metal fabrication, by fusing metal together through a variety of different methods. If your company is in need of the best metal fabrication services in the area, call 02 4872 3939 to talk to one of our customer service representatives. We can help with any project and will be happy to make recommendations and offer advice along the way. |